HS-850h

Product description

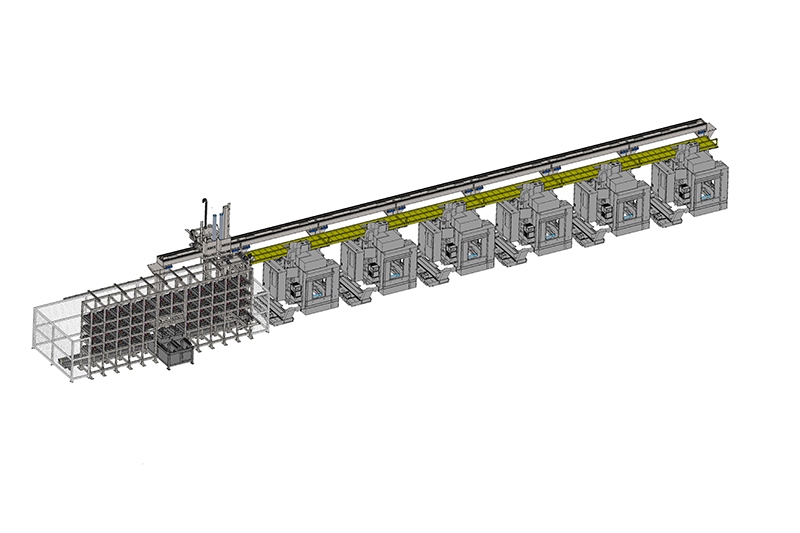

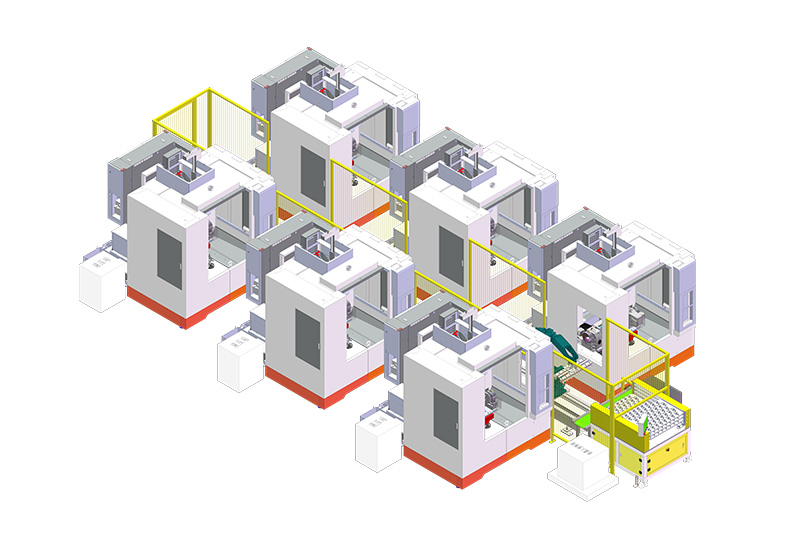

The line-and-track processing center series products are a collection of domestic and foreign products. They are based on advanced design concepts such as mechanical engineering, precision manufacturing technology and automation technology, and are learned through engineering After repeated simulation calculations and prototype trial production and appraisal, a new generation of CNC machine tools produced. This series of machine tools can complete a variety of sequential additions such as milling, drilling, tapping, and boring. It has multiple advantages such as fast moving speed, high spindle speed, and high efficiency. It is widely used in various types of boards, Mass production of precision parts such as housings and molds.

Product Features

High-precision spindle, assembled with P4 bearings, the maximum speed can reach 15000rpm.

The unique oil separator design completely separates the cutting fluid from the lubricating oil, prolongs the service life of the cutting fluid, and the waste oil can be recycled, which is economical and environmentally friendly.

The fully enclosed cover sheet metal design prevents the oil mist produced by the high-speed acceleration from affecting the environment and the physical health of the employees, which meets environmental protection requirements and a personalized design.

24T disc-type frequency conversion library, cam ATC changing device, fast changing time.

The three-axis drive system adopts direct drive, C3 grade precision ball screw and P grade roller guide, high rigidity, low friction and low noise.

can be equipped with a Taiwan-made four-axis linkage indexing plate or a five-axis indexing plate, which can meet the diverse and increasing needs of customers.

Scope of application: Mainly used in consumer electronics, mold processing, auto parts, medical equipment, aerospace, new energy and other industries.

| ⾏程X/Y/ Z | mm | 800/550/600 |

| Spindle end to work table | mm | 100-700 |

| Spindle center to Z axis guard | mm | 560 |

| Working table ruler | mm | 1000x500 |

| T-slot size (quantity x size x spacing) | mm | 6x18x80 |

| Maximum load of the workbench | kg | 600 |

| Maximum spindle speed | rpm | 12000 |

| Spindle power (continuous/25%) | kW | 7.5(11) |

| Spindle torque (continuous/25%) | N·m | 35.8(70) |

| Cutting speed | mm/min | 1-10000 |

| Rapid traverse speed X/Y/Z | m/min | 48/48/48 |

| ⼑Library form | # | Disc type (frequency conversion) |

| Number of tools | pcs | 24 |

| Positioning accuracy | mm | ±0.005/300 |

| repeat positioning accuracy | mm | ±0.003/300 |

| Machine weight | kg | 5800 |

| machine tool size | mm | 2300x3310x2750 |

Recommended Products

Copyright © 2021 HARVEST STAR TECHNOLOGY ALL RIGHT SERVER