HS-EG400

Product description

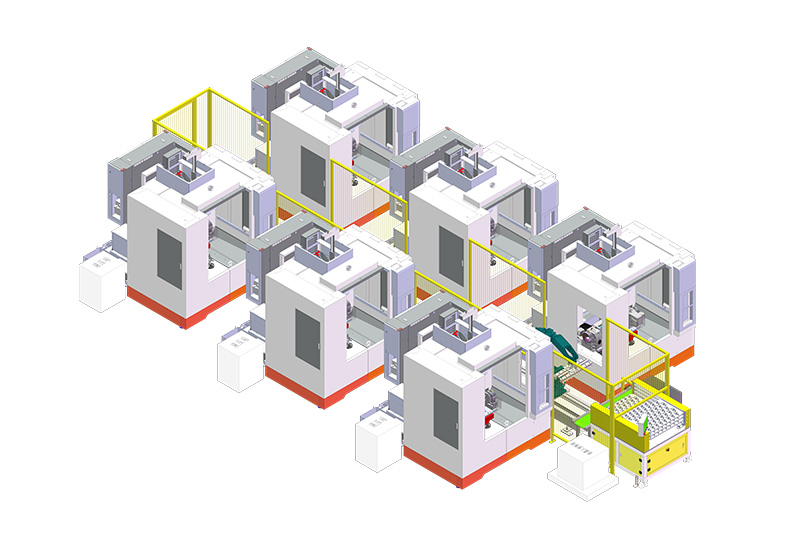

The high precision engraving and milling machine series products adopt a high-precision permanent magnet synchronous electric spindle of 36000rpm, which has high thermal stability and high precision; the long-standing structure design, the machine tool has a compact structure, good dynamic rigidity and stability High performance; using an integrated overall design, excellent interaction between the machine and the machine, the control of the machine tool is more user-friendly. It is mainly used for the addition of high-gloss, ceramic, glass, ink and other products in the 3C industry.

Product Features

adopts high-speed precision electric spindle, with high thermal stability and good machining accuracy;

Gantry structure design, compact machine tool structure, good dynamic rigidity and high stability;

The three-axis use precision screw and linear slide, which can improve the machining and positioning accuracy of the machine tool;

is equipped with a multi-head surrounding nozzle for cutting cooling, which has a good cooling effect;

can be installed with wireless probes, with on-line detection of workpieces, which can greatly reduce production costs.

Scope of application: applied to the processing of glass parts.

| ⾏程X/Y/Z | mm | 400/400/100 |

| Spindle ⿐ end to work table | mm | 130-230 |

| Main axis center to column | mm | 170 |

| ⼯Working table ruler | mm | 480x400 |

| T-slot size (quantity x size x spacing ) | mm | 5x12x80 |

| Maximum load of the workbench | kg | 60 |

| Maximum spindle speed | rpm | 40000 |

| Spindle power (continuous/25%) | kW | 4(4.8) |

| Spindle torque (continuous/25%) | N·m | 1.29(1.55) |

| Cutting speed | mm/min | 1-10000 |

| Rapid traverse speed X/Y/Z | m/min | 15/15/15 |

| ⼑Library form | # | Vertical style |

| Number of tools | pcs | 5 |

| positioning accuracy | mm | ±0.005/300 |

| repeat positioning accuracy | mm | ±0.003/300 |

| machine weight | kg | 1500 |

| machine tool size | mm | 1440x1550x1860 |

Recommended Products

Copyright © 2021 HARVEST STAR TECHNOLOGY ALL RIGHT SERVER