Runxing Technology invites you to appreciate the SIMM 2019 Shenzhen Machinery Exhibition

- Categories:Company News

- Author:

- Origin:

- Time of issue:2019-04-12 18:18

- Views:

Runxing Technology invites you to appreciate the SIMM 2019 Shenzhen Machinery Exhibition

- Categories:Company News

- Author:

- Origin:

- Time of issue:2019-04-12 18:18

- Views:

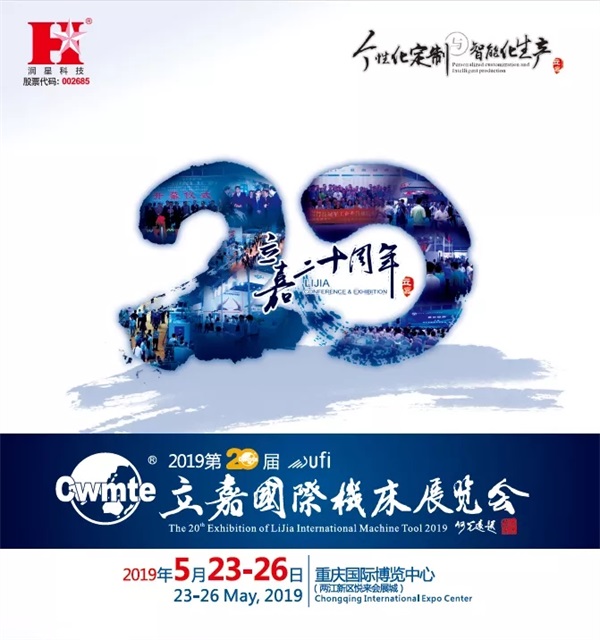

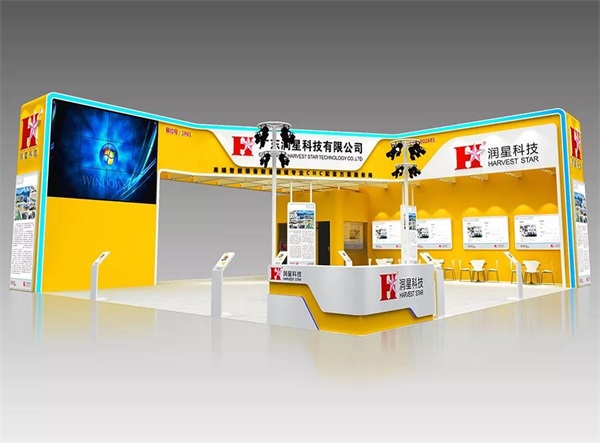

The 20th Shenzhen International Machinery Manufacturing Industry Exhibition (SIMM 2019 Shenzhen Machinery Exhibition) will be grandly opened at the Shenzhen Convention and Exhibition Center from March 28 to 31. With the theme of "precipitation, upgrading, breakthrough, and new encounters with manufacturing", this exhibition brings together more than 1,000 domestic and overseas industry leaders from more than 30 countries and regions, bringing intelligent manufacturing products and technologies to dedicate the innovative achievements of advanced manufacturing.

This year, SIMM continues to focus on intelligent manufacturing, with a total exhibition scale of 110,000 square meters, covering all aspects of metal cutting, metal forming, robotics and automation applications, laser processing technology, additive manufacturing, industrial measurement, cutting tools, precision parts processing, etc. Cutting-edge manufacturing technology and comprehensive solutions will bring you an unparalleled journey of industrial inter-chain.

At this exhibition, Runxing Technology will present four series of powerful products, covering intelligent multi-process flexible production lines, high-precision ceramic machining centers, high-precision vertical machining centers, high-load linear rail vertical machining centers, and high-speed gantry machining centers. And other series of products, involving 5G communications, various molds, auto parts and other application processing equipment.

Booth: Hall 1 1R01

210 square meters professional booth

Exhibits

Intelligent multi-process flexible production line

The solution integrates multiple processes such as machining, loading and unloading, cleaning, and testing of mobile phone shell workpieces. It fully automates the industry and greatly improves production efficiency; the combination of "2 machine tools + 1 robot" makes full use of robots; modular design, can be Quickly adjust according to the production products; drawer-type silo, which can load 5 trays at a time, can greatly increase the unmanned operation time of the unit and reduce the demand for personnel; integrated unit, reduce on-site construction, and can be quickly integrated with existing plant machine tools; maintenance The maintenance is convenient and does not affect the maintenance of the machine tool.

Application areas: processing non-ferrous metals, 3C industry, aluminum substrates, stainless steel, etc.

High precision ceramic machining center

High-precision ceramic machining center products are mainly used in the processing of high-gloss, ceramic, glass, graphite and other products in the 3C industry. They are designed with a gate structure, which has good processing rigidity and good precision. The machine tool spindle adopts a high-precision permanent magnet synchronous electric spindle, and the speed can reach 36000rpm, standard 12T umbrella tool magazine, optional wireless probe, can realize on-line inspection of workpieces, adopt fully enclosed cover sheet metal design, meet environmental protection requirements and humanized design, it is the ideal solution for small tool processing technology.

Application areas: high gloss, ceramics, glass, graphite, etc. in the 3C industry.

High-speed gantry machining center

The X and Y axes of the high-speed gantry machining center use linear motors with high precision. They are mainly used for processing various basic large parts, plates, disk parts, shell parts, molds, etc., of medium and small sizes and weights. After the workpiece is clamped once, it can automatically and efficiently complete various processes such as milling, drilling, boring, and reaming with high precision.

Application fields: aviation, heavy machinery, locomotive, shipbuilding, power generation, printing, textile, mold and other manufacturing industries.

High load-bearing linear rail vertical machining center

Linear rail vertical machining center series products are classic models developed to meet the requirements of high precision, high stability, and powerful fast cutting of precision molds or precision parts.

Application areas: electronics, molds, processing, new energy, automobiles, etc.

High precision vertical machining center

The linear rail vertical machining center is based on the advantages of domestic and foreign Lijia products, based on advanced design concepts such as ergonomics, precision manufacturing technology and automation technology, after repeated simulation calculations of engineering mechanics, and the appraisal and trial production of prototypes. A new generation of CNC machine tools produced. This type of machine tool is widely used in the mass production of various plates, shells and other precision parts.

Application areas: electronics, molds, processing, new energy, automobiles, etc.

Recommended News

Copyright © 2021 HARVEST STAR TECHNOLOGY ALL RIGHT SERVER