Runxing Technology invites you to visit the 2019 Guangdong Industry Fair & Guangdong-Hong Kong-Macao Advanced Manufacturing Expo

- Categories:Company News

- Author:

- Origin:

- Time of issue:2019-08-02 19:21

- Views:

Runxing Technology invites you to visit the 2019 Guangdong Industry Fair & Guangdong-Hong Kong-Macao Advanced Manufacturing Expo

- Categories:Company News

- Author:

- Origin:

- Time of issue:2019-08-02 19:21

- Views:

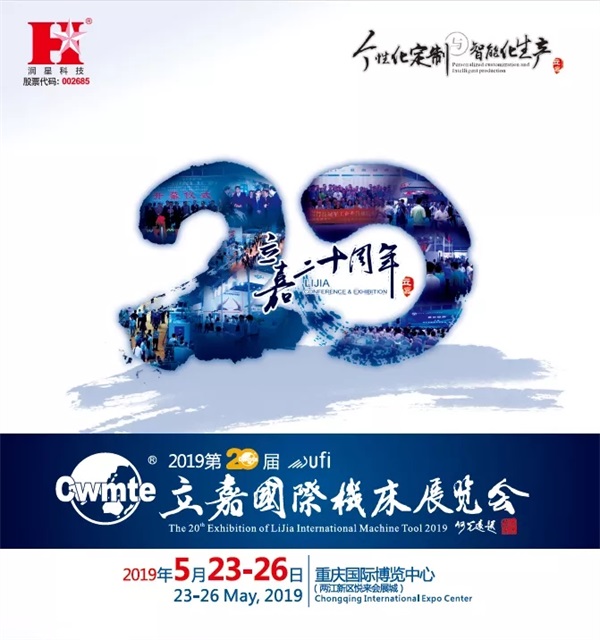

Exhibition Introduction

The 2019 Guangdong Industry Fair & Guangdong-Hong Kong-Macao Advanced Manufacturing Expo will be held at the China Import and Export Fair Complex on August 8-11. The total exhibition area is expected to reach 60,000 square meters. The five categories of exhibits accurately meet market needs, and more than 1,000 A variety of subdivided exhibits cover the needs of the broad market, and will use multiple scenarios such as brand new image display, forward-looking think tank forums, diversified social activities, and experiential technology displays as breakthrough points to fully present China’s current leading high-end equipment technology, intelligence New technologies, new formats, and new models in manufacturing, automobile manufacturing, precision manufacturing and other industries. At that time, it will attract the attention of customers from home and abroad with a more high-end, more professional, more open, more modern, and more international appearance.

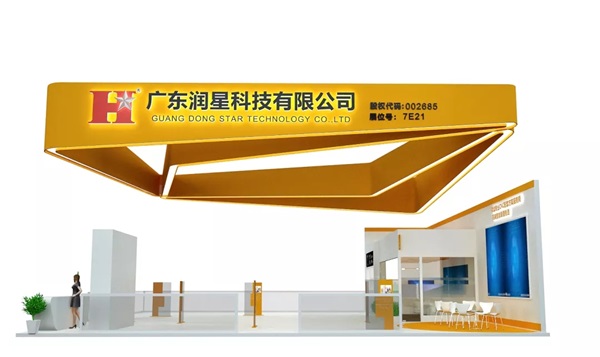

Runxing Booth: 1E11

In this exhibition, Runxing Technology will bring its independent research and development linear rail vertical machining center, hard rail vertical machining center, drilling and tapping machining center, gantry machining center, and intelligent multi-process flexible production unit to appear. We sincerely invite you to visit and guide at booth 1E11 .

Exhibits

HS-850HD

The linear rail vertical machining center is based on the advantages of domestic and foreign Lijia products, based on advanced design concepts such as ergonomics, precision manufacturing technology and automation technology, after repeated simulation calculations of engineering mechanics, and the appraisal and trial production of prototypes. A new generation of CNC machine tools produced. This type of machine tool is widely used in the mass production of various plates, shells and other precision parts.

HS-1066H

The linear rail vertical machining center is based on the advantages of domestic and foreign Lijia products, based on advanced design concepts such as ergonomics, precision manufacturing technology and automation technology, after repeated simulation calculations of engineering mechanics, and the appraisal and trial production of prototypes. A new generation of CNC machine tools produced. This type of machine tool is widely used in the mass production of various plates, shells and other precision parts.

HS-1690

The series of hard-track vertical machining centers are classic designs for high-precision, high-stability, and powerful fast cutting of precision molds or precision parts.

HS-1712

High-speed gantry machining center, X, Y axis is driven by FANUC linear motor, stable movement, low noise, high processing accuracy, mainly used for various basic large parts, plates, plate parts, shells of medium and small size and weight. Body parts, molds and other parts are processed. After the workpiece is clamped once, it can automatically and efficiently complete the milling, drilling, boring, reaming and other processes with high precision.

HS-1050T

The series of high-speed drilling and tapping processing centers are developed based on the most popular and advanced design concepts of flexible machine tools in the world. They are mainly used for processing non-ferrous metals, 3C industries, aluminum substrates, stainless steel and other drilling and tapping processes. It can realize drilling and milling processing with fast moving speed and high spindle speed. The efficiency and quality of drilling and tapping are more than 10 times that of ordinary machining centers. For customers in 3C, communications and other industries, it is the most ideal processing equipment.

Intelligent multi-process flexible production unit

The solution integrates multiple processes such as machining, loading and unloading, cleaning, and testing of mobile phone shell workpieces. It fully automates the industry and greatly improves production efficiency; the combination of "2 machine tools + 1 robot" makes full use of robots; modular design, can be Quickly adjust according to the production products; drawer-type silo, which can load 5 trays at a time, can greatly increase the unmanned operation time of the unit and reduce the demand for personnel; integrated unit, reduce on-site construction, and can be quickly integrated with existing plant machine tools; maintenance The maintenance is convenient and does not affect the maintenance of the machine tool.

Recommended News

Copyright © 2021 HARVEST STAR TECHNOLOGY ALL RIGHT SERVER