Exhibition invitation | Only 2 days left before the opening of the 2019 DMP (Dongguan) Smart Expo

- Categories:Company News

- Author:

- Origin:

- Time of issue:2019-05-06 18:24

- Views:

Exhibition invitation | Only 2 days left before the opening of the 2019 DMP (Dongguan) Smart Expo

- Categories:Company News

- Author:

- Origin:

- Time of issue:2019-05-06 18:24

- Views:

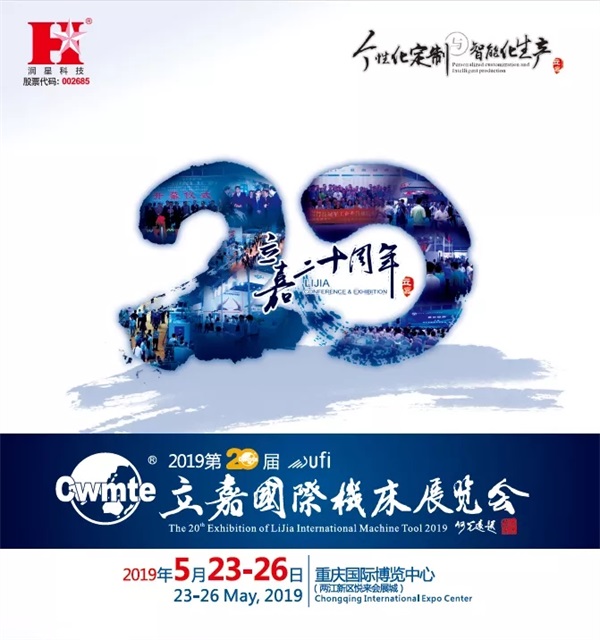

As one of the most influential and largest mold, machine tool and plastic machinery exhibitions in South China, DMP Smart Expo will also present a different new atmosphere as the exhibition period is advanced from November to May.

Guangdong International Robot and Intelligent Equipment Expo ("Smart Expo") is approved by the People’s Government of Guangdong Province. It is sponsored by the Department of Industry and Information Technology of Guangdong Province and the People’s Government of Dongguan. Organized by the government and Hong Kong Paper Communication Exhibition Co., Ltd., it adopts the innovative exhibition mode of "government-organized meetings and corporate exhibitions" and the idea of "marketization, internationalization, and professionalization". The professional annual exhibition with the theme of parts and components has been held three times since 2015. The holding of the Smart Expo is an important measure to implement "Made in China 2025" and to promote the development of the robot and intelligent equipment industry through the introduction of supply based on demand.

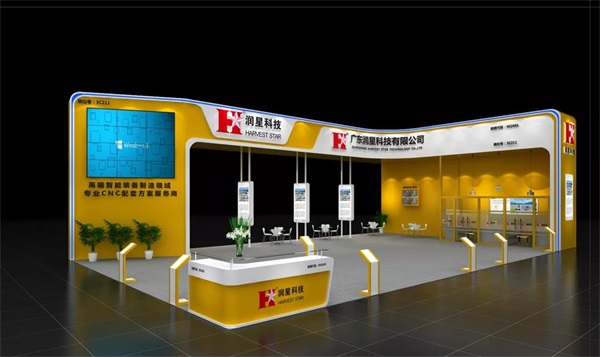

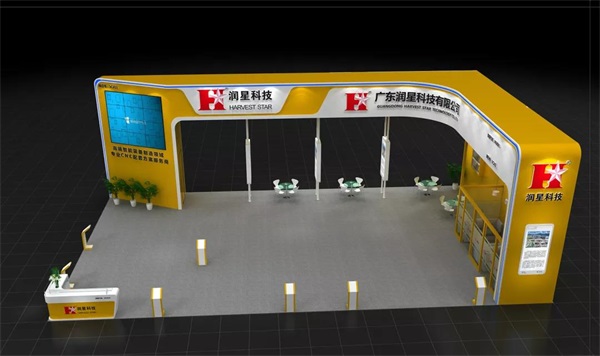

The 2019 DMP Dongguan Smart Expo will be held at the Guangdong Modern International Exhibition Center (Houjie) from May 8th to 11th. The exhibition area is about 80,000 square meters. More than a thousand well-known companies at home and abroad will compete on the same stage.

Runxing Booth: 3C211

Runxing Exhibits

HS-500T+HSRO770

The "machine tool + robot" multi-process integration scheme is a combination of "2 machine tools and 1 robot", which makes full use of robots; modular design, which can be quickly adjusted according to the production product; drawer-type silo, which can hold 5 trays at a time, which can greatly Increase the unmanned operation time of the unit and reduce the demand for personnel; The integrated unit reduces on-site construction and can be quickly integrated with the existing plant machine tools;

It is suitable for machining, loading and unloading, grinding, equipment, etc. in the 3C industry.

B-500S

High-precision ceramic machining center products are mainly used in the processing of high-gloss, ceramic, glass, graphite and other products in the 3C industry. They are designed with a gate structure, which has good processing rigidity and good precision. The machine tool spindle adopts a high-precision permanent magnet synchronous electric spindle, and the speed can reach 36000rpm, standard 12T umbrella tool magazine, optional wireless probe, can realize on-line inspection of workpieces, adopt fully enclosed cover sheet metal design, meet environmental protection requirements and humanized design, it is the ideal solution for small tool processing technology.

3C industry's high gloss, ceramics, glass, graphite, etc.

HS-850HD

The linear rail vertical machining center is based on the advantages of domestic and foreign Lijia products, based on advanced design concepts such as ergonomics, precision manufacturing technology and automation technology, after repeated simulation calculations of engineering mechanics, and the appraisal and trial production of prototypes. A new generation of CNC machine tools produced. This type of machine tool is widely used in the mass production of various plates, shells and other precision parts.

Electronics, molds, processing, new energy, automobiles, etc.

HS-1066H

The linear rail vertical machining center is based on the advantages of domestic and foreign Lijia products, based on advanced design concepts such as ergonomics, precision manufacturing technology and automation technology, after repeated simulation calculations of engineering mechanics, and the appraisal and trial production of prototypes. A new generation of CNC machine tools produced. This type of machine tool is widely used in the mass production of various plates, shells and other precision parts.

Electronics, molds, processing, new energy, automobiles, etc.

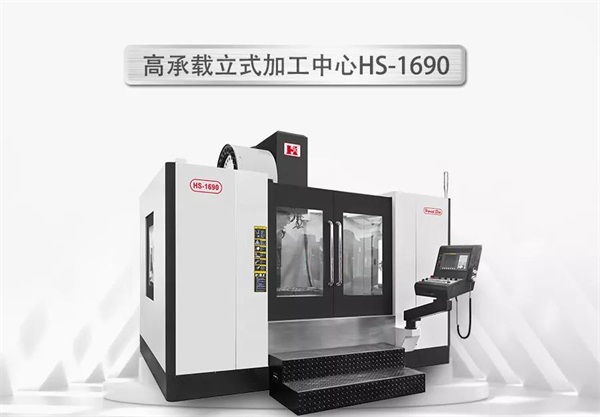

HS-1690

The series of hard-track vertical machining centers are classic designs for high-precision, high-stability, and powerful fast cutting of precision molds or precision parts.

Electronics, molds, processing, new energy, automobiles, etc.

HS-1370H

The series of hard-track vertical machining centers are classic designs for high-precision, high-stability, and powerful fast cutting of precision molds or precision parts.

Electronics, molds, processing, new energy, automobiles, etc.

Recommended News

Copyright © 2021 HARVEST STAR TECHNOLOGY ALL RIGHT SERVER