Runxing Technology invites you to visit Shenzhen's new world-class convention and exhibition center, the first Greater Bay Area Industrial Expo

- Categories:Company News

- Author:

- Origin:

- Time of issue:2019-11-25 11:28

- Views:

Runxing Technology invites you to visit Shenzhen's new world-class convention and exhibition center, the first Greater Bay Area Industrial Expo

- Categories:Company News

- Author:

- Origin:

- Time of issue:2019-11-25 11:28

- Views:

The last finale exhibition in 2019

The first Shenzhen Greater Bay Area Industry Fair

200,000+m² exhibition area

8000+ booths

1800+ exhibitors

130,000+ professional visitors

November 26-29, 2019

2019 Greater Bay Area Industry Expo and the 22nd DMP International Mould, Metal Processing, Plastic and Packaging Exhibition

Will be in Shenzhen's new world-class exhibition hall-Shenzhen International Convention and Exhibition Center

held with grandeur

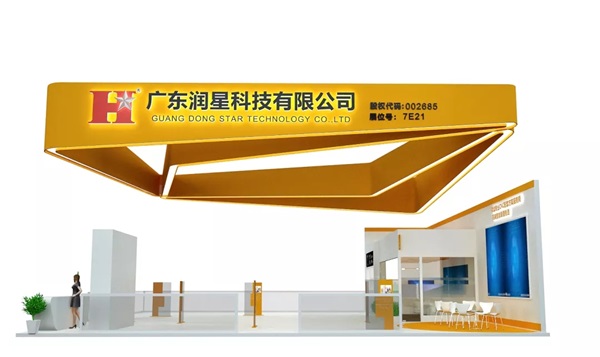

Runxing Technology will bring a new generation of technology upgrade processing center, intelligent manufacturing flexible production unit to a grand exhibition

Booth: E21, No.7, Shenzhen Convention and Exhibition Center

Add a touch of color to the booming Bay Area construction

Runxing Booth: 7E21

Exhibits

The series of high-speed drilling and tapping processing centers are developed based on the most popular and advanced design concepts of flexible machine tools in the world. They are mainly used for processing non-ferrous metals, 3C industries, aluminum substrates, stainless steel and other drilling and tapping processes. It can realize drilling and milling processing with fast moving speed and high spindle speed. The efficiency and quality of drilling and tapping are more than 10 times that of ordinary machining centers. For customers in 3C, communications and other industries, it is the most ideal processing equipment.

The graphite processing center is mainly used for the processing of graphite profiles. It adopts a special dust-proof and dust-removing device and is equipped with a powerful dust-absorbing device, which can efficiently suck and remove graphite dust during processing. It has a special design for the spindle and feed system to facilitate cleaning and avoid dust Pollution; suitable for precision machining of graphite molds, etc.

The solution integrates multiple processes such as machining, loading and unloading, cleaning, and testing of mobile phone shell workpieces. It fully automates the industry and greatly improves production efficiency; the combination of "2 machine tools + 1 robot" makes full use of robots; modular design, can be Quickly adjust according to the production products; drawer-type silo, which can load 5 trays at a time, can greatly increase the unmanned operation time of the unit and reduce the demand for personnel; integrated unit, reduce on-site construction, and can be quickly integrated with existing plant machine tools; maintenance The maintenance is convenient and does not affect the maintenance of the machine tool.

The linear rail vertical machining center is based on the advantages of domestic and foreign Lijia products, based on advanced design concepts such as ergonomics, precision manufacturing technology and automation technology, after repeated simulation calculations of engineering mechanics, and the appraisal and trial production of prototypes. A new generation of CNC machine tools produced. This type of machine tool is widely used in the mass production of various plates, shells and other precision parts.

The linear rail vertical machining center is based on the advantages of domestic and foreign Lijia products, based on advanced design concepts such as ergonomics, precision manufacturing technology and automation technology, after repeated simulation calculations of engineering mechanics, and the appraisal and trial production of prototypes. A new generation of CNC machine tools produced. This type of machine tool is widely used in the mass production of various plates, shells and other precision parts.

The series of hard-track vertical machining centers are classic designs for high-precision, high-stability, and powerful fast cutting of precision molds or precision parts.

Runxing Technology is a professional CNC supporting program service provider focusing on the consumer electronics industry and intelligent equipment manufacturing. The predecessor of the company was established in the 1980s, and was officially registered as "Runxing Machinery" in 2007. It covers an area of approximately 70,000 square meters. It has been recognized as a national high-tech enterprise, an advanced collective of the national machinery industry, and a manufacturing enterprise in Guangdong Province. Top 500, Guangdong Province Famous Brand, Guangdong Province Famous Brand Product, Guangdong Province Contract-abiding and Trustworthy Enterprise, Guangdong Province Strategic Emerging Industry (Intelligent Manufacturing Field) Key Enterprise.

Runxing Technology specializes in the research and development, production, sales and service of CNC machine tools. The products cover more than 60 products of drilling, tapping, gantry, horizontal, engraving and milling, and industrial robots. The monthly output of manufacturing exceeds 1,500 units, and the products are widely used. In the fields of consumer electronics, automobile manufacturing, mold manufacturing, clocks and meters, textiles and apparel, medical equipment, aerospace, new energy, automation, etc., it has been verified by more than 6000 customers, and the total number of equipment in the market exceeds 30,000. It is South China A leading enterprise in the entire industry chain of CNC machine tools.

Recommended News

Copyright © 2021 HARVEST STAR TECHNOLOGY ALL RIGHT SERVER